- 商品详情

PRODUCT DESCRIPTION

KSD314-N series thermostat is a primary action (SOD) overheat protector. Its characteristic is that after reaching the operating temperature, the thermostat will be disconnected and kept until it is turned back on, which acts like a fuse. The product's disconnection temperature is not affected by the operating current, so its rated current can reach 35A, which is better than the fuse.

The product contacts are single-pole single-throw (SPST), and the housing is made of high-temperature resistant resin material with a maximum operating temperature of 140C. The pressure rating is basic insulation, and certain additional measures can be taken to achieve a reinforced insulation level. The standard load nature is purely resistive, providing micro-disconnection.

BASIC TECHNICAL PARAMETERS

Sub-series | Action type | Switch type | Rated current (resistive load) | Operating temperature OT. |

KSD314-V | Auto reset | SPST、NC/NO | 35A | 30~180°C(TUV)30~140°C(UL) |

KSD314-R & KSD314-R-C | Manual reset | SPST、NC | 35A | 40~140°C |

KSD314-N | SOD | SPST、NC | 35A | 40~140°C |

KSD314-T | PTC cutoff,Voltage maintain type | SPST、NC | 35A | 55~140°C |

KSD314-Q | Double functions-Auto reset and one shot type | SPST、NC | 45A | 30~100°C |

KSD314-F (developing) | SPDT type Auto reset | SPDT | 25A | 30~140°C |

KSD314-W (developing) | Auto reset with thermal compensation | SPST、NC | 25A | 30~140°C |

Tmax:

OT:70°C | OT:71~180°C | |

140°C(L) 170°C (S) | 205°C (L) 235°C (S) |

L: Long term

S:Less than 15 min

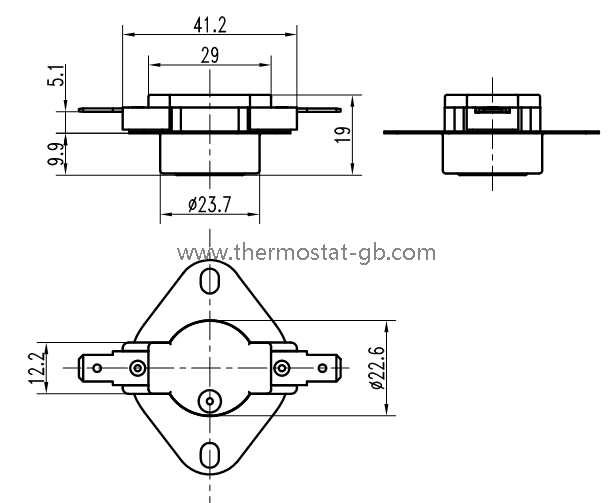

DIMENSION OF THE MAIN BODY

SAFETY CERTIFICATE

OT | Life cycles | 400V/250V/125V 35A |

40~140°C | 1 (SOD) | TUV/UL |

INSTALLATION AND DIRECTION FOR USE

| Installation and use instructions: |

| 1. Grounding method: Connected to the grounding metal parts of the equipment through the metal casing of the thermostat. 2. The thermostat shall be operated in a general indoor environment where the relative humidity of the air is not more than 90%, no corrosive gas, no flammable gas and conductive dust. 3. When the temperature controller is in contact with the temperature, the cover should be placed close to the heat-generating part of the controlled appliance, and the thermal surface of the cover should be coated with thermal grease or other similar heat-conducting medium. 4. When the temperature controller is exposed to liquid or steam, it is recommended to use a stainless steel cover and a reliable leak-proof measure to prevent liquid from seeping into the insulation of the thermostat. 5. It is not possible to collapse or deform the top of the cover to avoid changes in operating temperature or other properties. 6. Do not allow liquid to penetrate inside the thermostat! The housing must be protected from excessive forces to prevent cracking; the housing should be kept clean to prevent contamination of conductive materials to prevent short-circuit breakdown due to reduced insulation. 7. The terminal cannot be bent during use, otherwise the reliability of the electrical connection will be affected. |